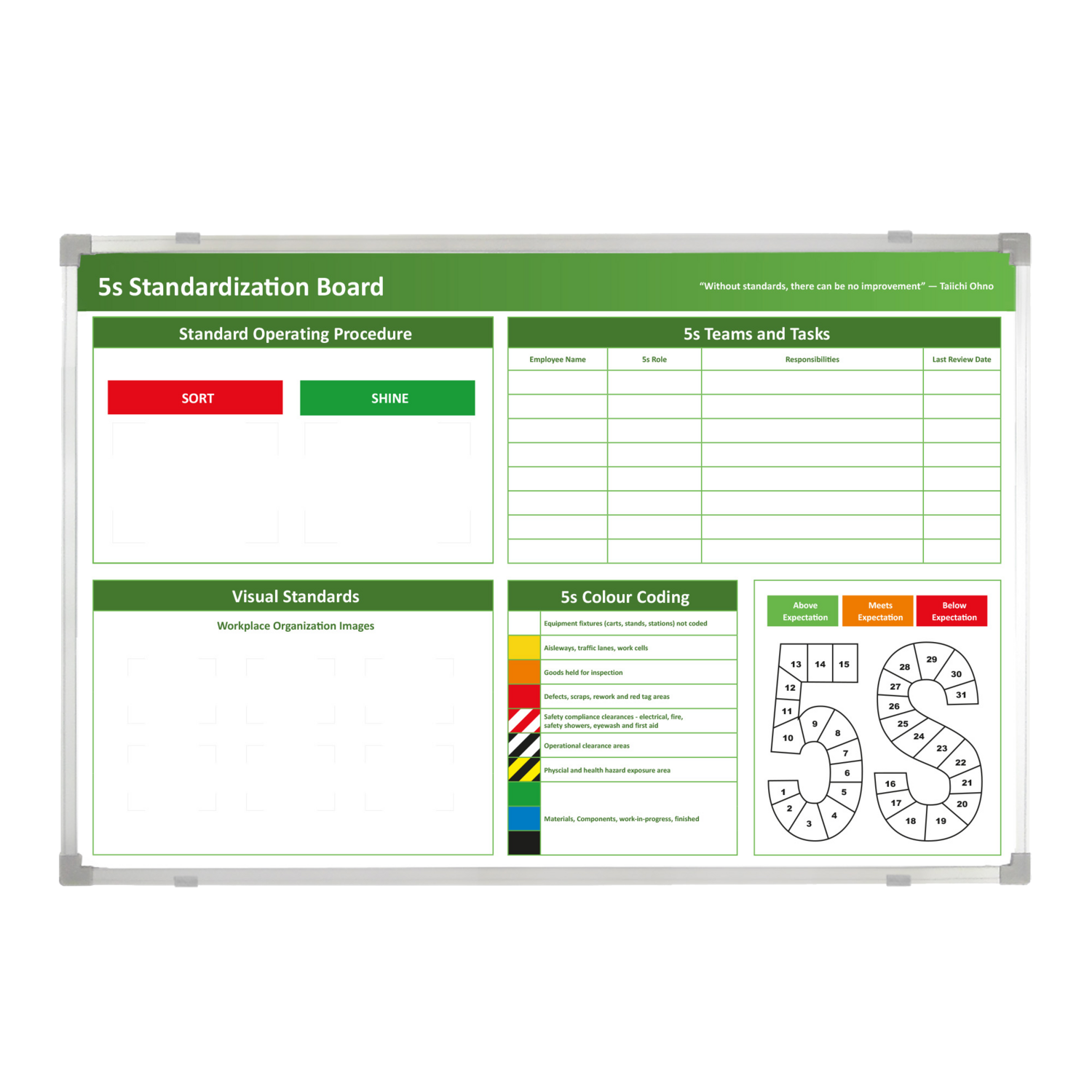

The main aim of the standardization board is to help employees visualize the agreed standards for Sort and Shine and allocate responsibilities for the 5S activities. It also gives a clear visual of the daily 5S performance against the visual standards and set procedures.

Product Features

- Board size 6′ x 4′

- Magnetic dry wipe whiteboard with 10 year surface guarantee

- Dye sublimation printing process

- Includes 2 Solo Magnetic Document Holder Windows in black

- Smart anodized aluminum frame

- Includes screws and fixings

Sort and Shine form the foundation of the 5S system and there is a strong need to ensure that the methods in which these are performed are communicated effectively to everyone. Standard operating procedure (SOP) specifies in writing the current best practices. It establishes a systematic way of doing work and ensures that work is done consistently. Your printed letter procedures for Sort and Shine are displayed through the 2 letter magnetic paper holder windows which are included with the board.

The 5S Teams and Tasks identifies which employee is responsible for the various 5S activities. There is a date column to clearly show when the last review took place.

Standardization is a fundamental starting point for improvement work. There is a strong need for the improvement activities to be reviewed on a regular basis. For effective 5S implementation, personnel must be given responsibilities and take accountability for sustaining the initiatives.

The 5S calendar is to be filled in every day by coloring the respective boxes in green , orange or red to depict above, below or meets expectations. This also gives a clear visual to Management as to how the team is performing.

Successful 5S implementation is to be performed systematically and consistently. Maintaining a calendar to evaluate the performance of the 5S activities on a daily basis helps personnel gain a comprehensive understanding of their progress and encourages them to take corrective action to improve where necessary.

Standardization does not only apply to processes but also to the workshop and the office through labelling and color coding. This not only guarantees optimal workplace organization but also prevents accidents. The 5S Color Coding section shows which colors’ correspond to the Health and Safety regulations.